Assembly Test

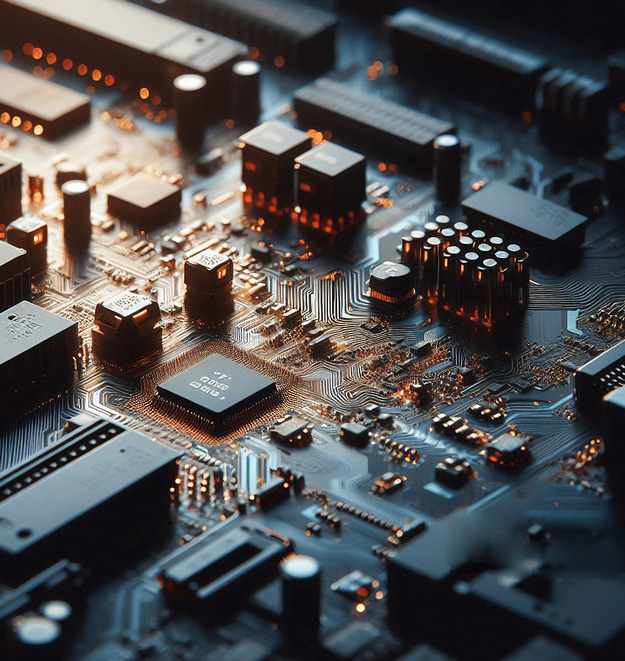

Quality and defect-free printed circuit boards (PCBs) are important for the proper functioning of any electronic device. Although PCB manufacturing is largely automated, some of these boards may have manufacturing defects. Left unattended, these manufacturing defects can lead not only to equipment failure, but also to product recalls and wasted money and time. To avoid these, PCBs are tested using different techniques at each stage of manufacture. Functional testing (FCT) is a type of PCB testing performed in the final stages of manufacturing after visual and AOI inspections are complete. It provides insights into PCB quality and helps identify manufacturing defects such as missing components, shorts, opens, incorrect component placement, and more. Kingford provides various types of PCB inspection and testing services, including PCB functional testing.